28 Aug Data Center Energy-Efficiency Improvement

🚀 Boost Your Data Center Efficiency & Reduce Costs! 🚀

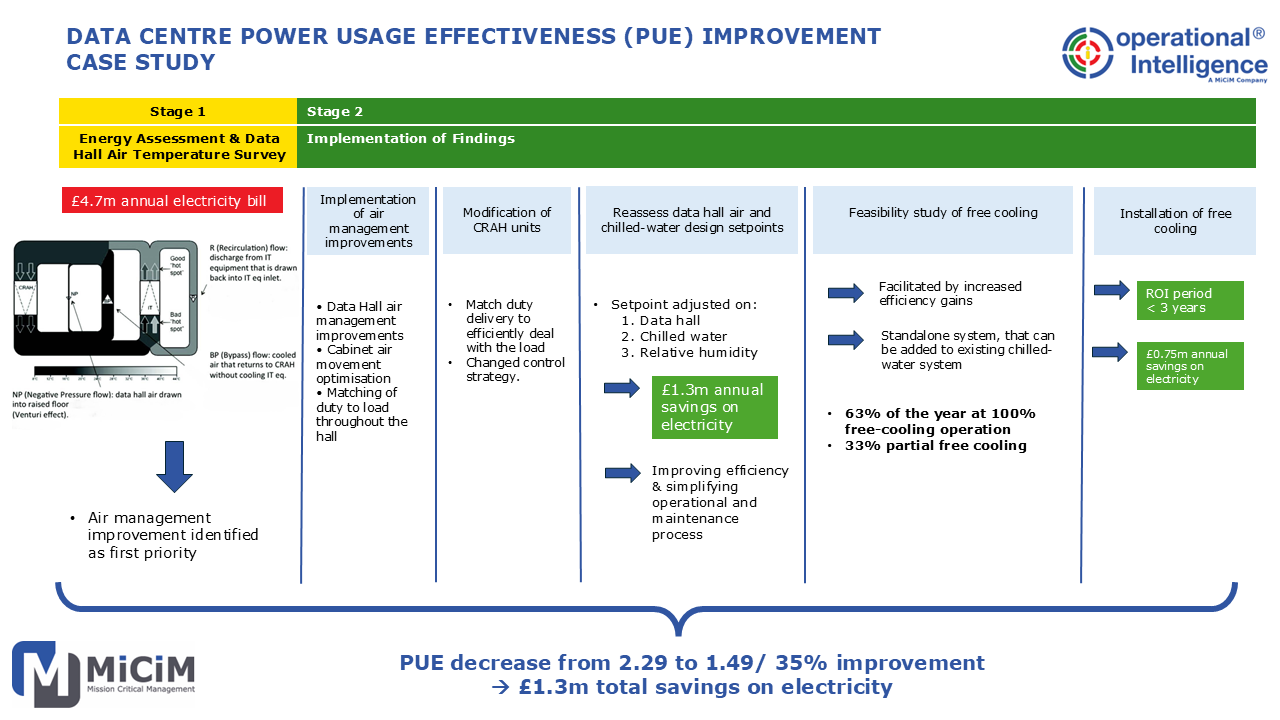

In a recent energy assessment exercise, Operational Intelligence, part of the MiCiM group, assisted a global financial services firm achieve a 35% reduction in data center energy usage—saving them £1.3 million annually! Through targeted upgrades, including air management, cooling system optimisations, and the adoption of free cooling, the recommendation of the OI team resulted in reducing the PUE of the data center from 2.3 to 1.49. These improvements not only cut costs but also enhanced reliability and simplified operations.

Background

The data centre in question was originally built in the early 2000’s and featured a traditional chilled-water cooling system. At the start of the improvement program the facility had a Power Usage Effectiveness (PUE) of 2.3, which is considerably higher than the industry target of 1.2 or lower for modern data centers. PUE is a key metric in assessing data center energy efficiency, representing the ratio of total facility energy consumption to the energy used by IT equipment alone. This high PUE indicated significant potential for energy optimisation, particularly in the cooling systems, which were found to be the largest consumers of energy after the IT equipment.

The Improvement Program

The energy efficiency initiative that Operational Intelligence conducted was structured into several phases, starting with an energy assessment and a detailed survey of the data hall’s air temperatures. These assessments highlighted substantial inefficiencies, such as excessive air recirculation and bypass within the cooling system, which contributed to unnecessary energy consumption.

Following the assessment, a series of targeted improvements were recommended by OI and implemented:

- Air Management Enhancements: The team introduced targeted air management improvements throughout the data hall. These steps were critical in minimizing the mixing of hot and cold air streams, which allowed for more precise control of the cooling system.

- Cooling Unit Modifications: The operation of the computer room air handling (CRAH) units were amended in line with our findings to improved air management. Additionally, the control strategy for these units was changed further enhancing efficiency.

- Temperature Setpoint Adjustments: Over several months, the team gradually amended the setpoints for both air and chilled water temperatures. This careful, phased approach ensured that reliability was maintained while optimising energy use.

- Free Cooling Implementation: A feasibility study was conducted to explore the possibility of incorporating free cooling to the existing chilled water system. This led to the installation of additional equipment to the system, which enabled partial or full free cooling for the majority of the year, significantly cutting energy costs.

Results and Impact

The comprehensive improvement program resulted in a remarkable 35% reduction in the facility’s PUE, bringing it down to 1.49. This translated into annual energy cost savings of approximately £1.3 million, reducing the data centre’s total electricity bill from £3.6 million to £2.3 million. Notably, these changes were made without compromising the data centre’s high availability and reliability, a critical concern for the financial services firm.

In addition to the energy and cost savings, the approach of the team to the project fostered a culture of continuous improvement and collaboration among the facility management and IT infrastructure teams. Equally, the firm, by providing training and involving the operational team in the process, empowered its employees to take ownership of the energy-efficiency initiatives, leading to sustained performance improvements and enhanced morale.

Conclusion

This case study demonstrates that even legacy data centres with high reliability requirements can achieve significant energy savings through well-planned and executed efficiency programs. By leveraging engineering expertise and best practices in air management and cooling optimisation, Operational Intelligence was able to enable the client to reduce both its environmental impact and operational costs, setting a strong example for others in the industry.

If you’re looking to drive similar results and ROI in under 3 years, it’s time to take action. 🌍 Reach out to us at enquiries@micim.co.uk or call +44 (0)118 9500440 to find out more about how we can help.